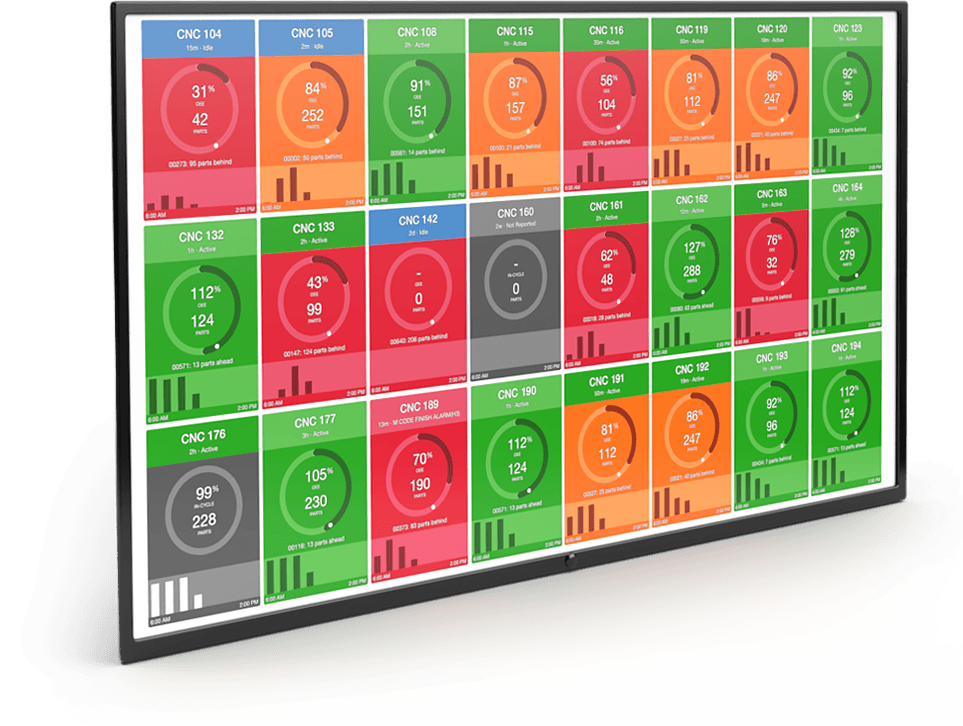

Build more with real-time data. Put analytics to work and start driving more reliable, efficient operations for your heavy machinery manufacturing units.

USE CASES

Learn how Heavy Equipment Manufacturers can solve their largest challenges with Industrial IoT and discover practical solutions for rolling out successful IIoT implementations.

The global oil and gas equipment and services sector is projected to achieve nearly 4% annual growth up to 2026.

Manufacturers in this industry must leverage every available advantage to maintian the competetive edge .

Staying ahead in the market requires constant innovation and strategic planning

Adapting to evolving market market dynamics is crucial for sustained growth and success in the oil and gap equipment and services sector

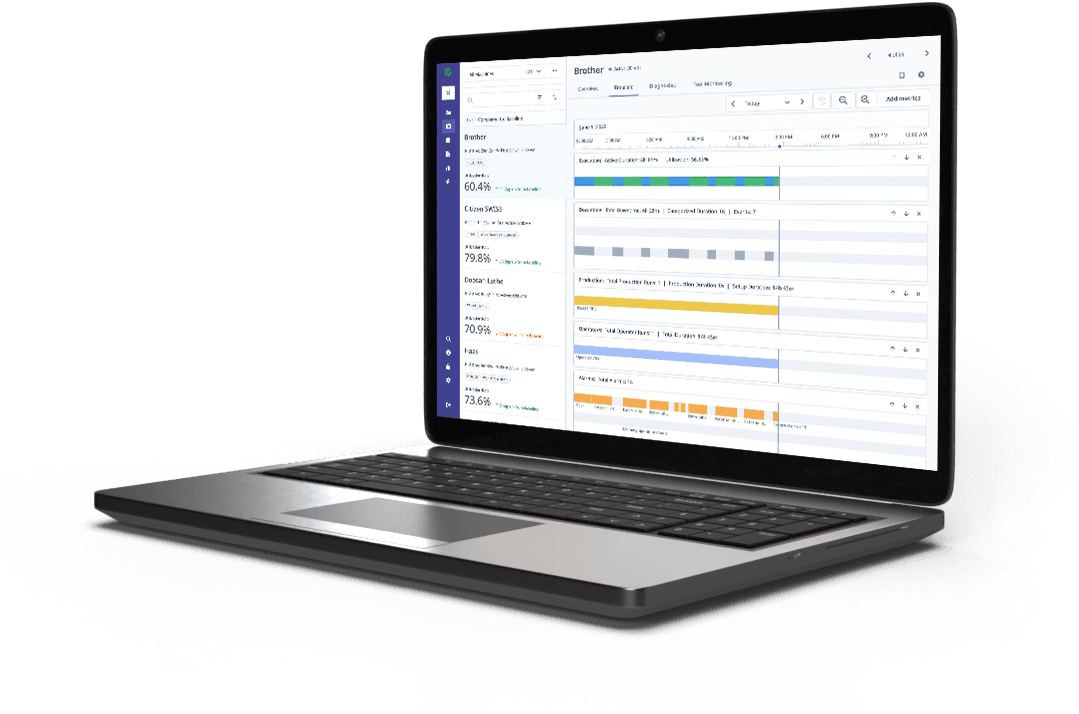

Automotive suppliers should develop an IoT strategy that harnesses the existing expertise within their factory.

An empowered IoT platform is essential for automotive suppliers to effectively utilize their machine data

The time has come to unlock the potential of machine data within automotive manufacturing

Leaveraging the machine can lead to improved efficiency and innvotion in the automative supply chain

Heavy equipment manufacturers face challenges such as shrinking profit margins and tighter production schedules.

Real-time production data can be a valuable resource to address these challenges

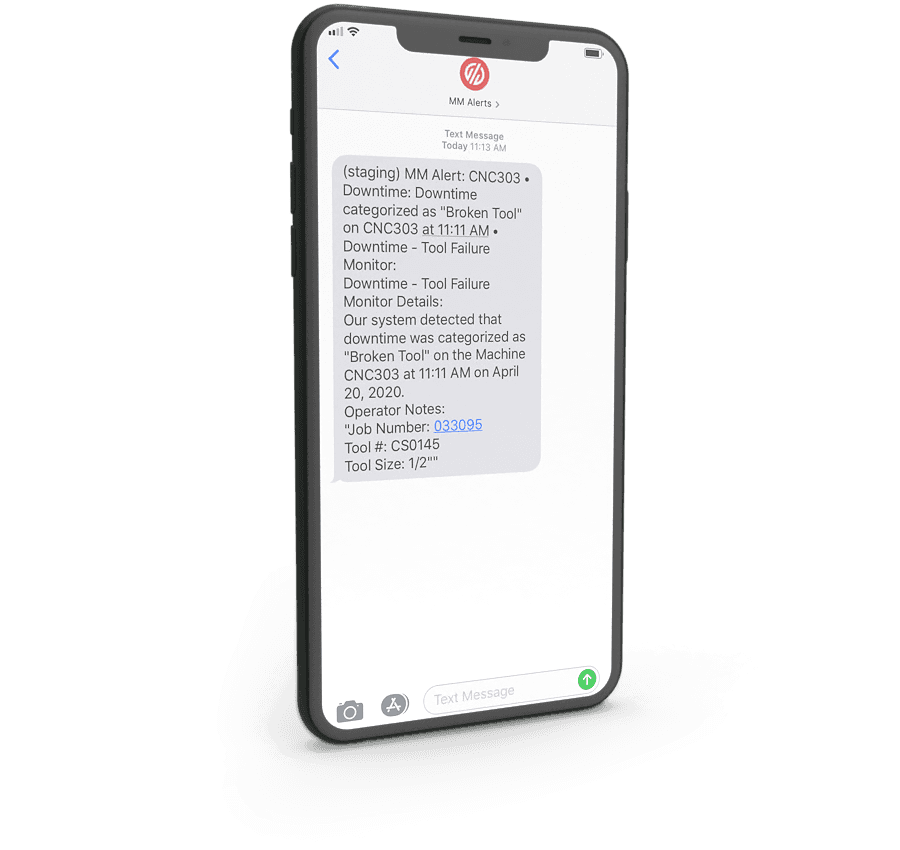

We offer support and solution to help heavy equipment manufactures navigate these industry pressures .

Count on us to provide the tools and expertise needed to thrive in the evolving heavy equipment manufacturing landscape

Escalating competition and pricing pressures emphasize the Urgency for MedicaL Device manufacturers to excel in product development

Delivering to top-quality medical devices swiftly has become paramaount objective in this competetive landscape

Manufacturers must prioritize efficiency and innovation to maintain a competetive edge in the medical device industry

Meeting the demand in fast-paced market is critical for success in the medical device sector amidst and heightened competition and price constraints.

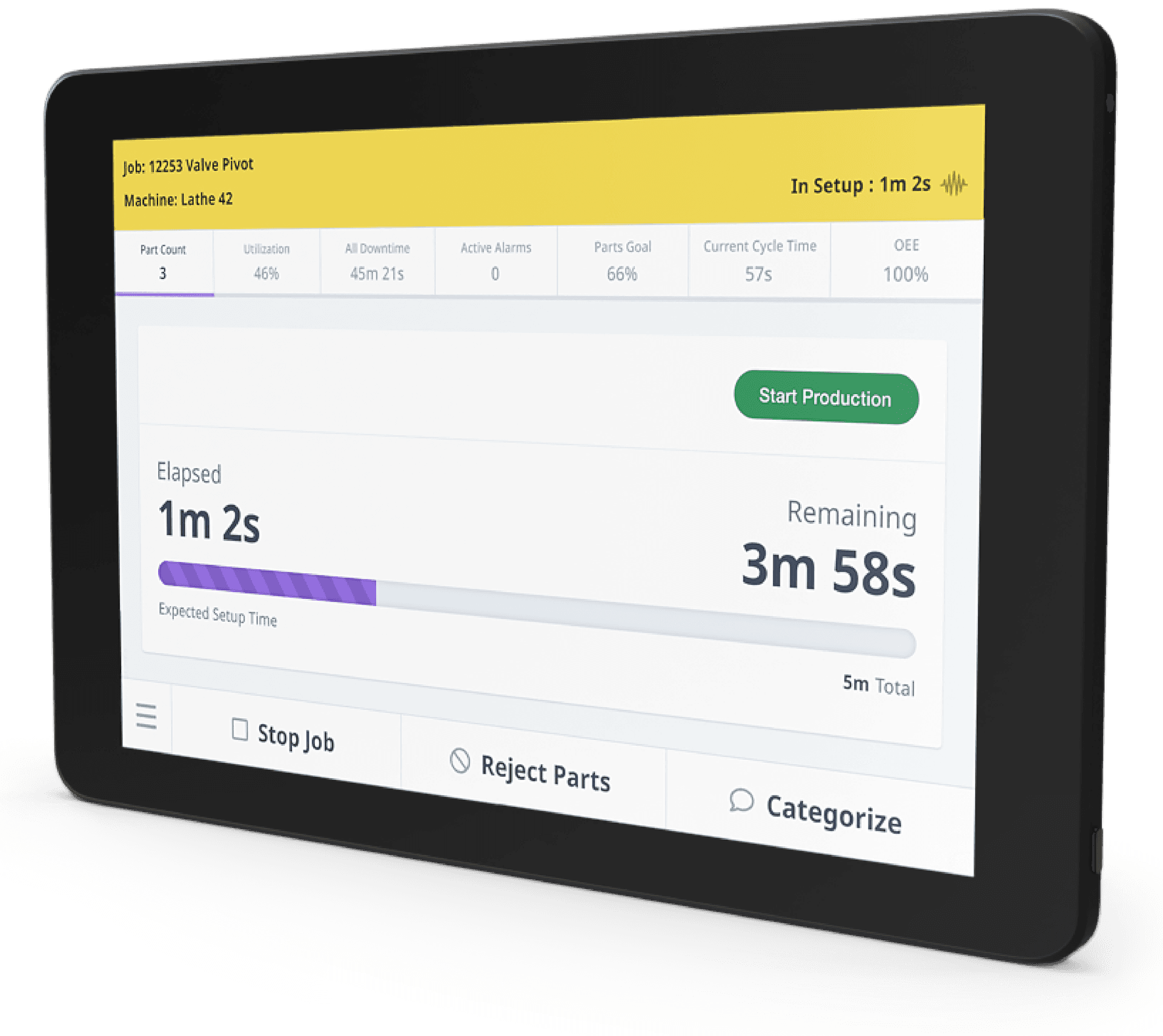

Want to see MachinoX Pro in action first? BOOK FREE TRIAL